Company Profile Company Name:Geili Machinery (Fujian) Group Co., LtdContact Person:Vicky YuTel :86-594-6975208 Fax:86-594-6975166 Email:vicky@rerollingmillccm.com

Product Description:

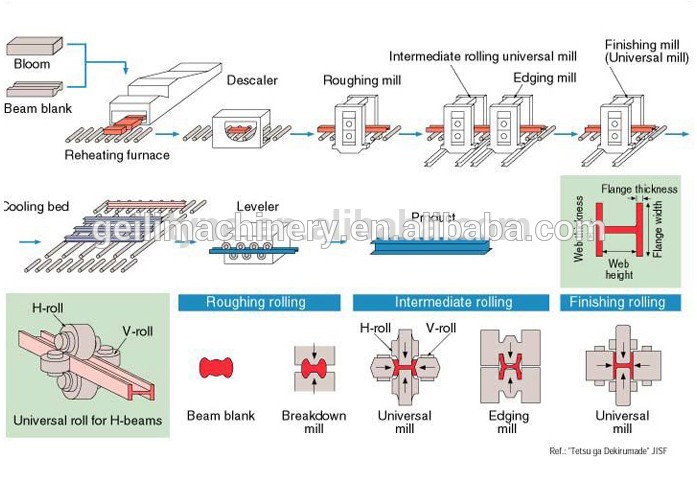

Hot rolling mill is a mill or factory where ingots of heated metal are passed between rollers to produce sheets

or bars of a required cross section and form.

Rolling Mill Process

Heating furnace -----> come out furnace / CCM----->Rough Roll -----> Intermediate Roll--->

Pre-finish Roll ----> finished product ---->packing

Company profile:

Fujian Geili Machinery Manufacturing Co., Ltd is a manufacturer specialized in research, development, manufacture

and sales of continuous casting machine in China. Our company owns a group of high quality R & D team and

professional & efficient management staff. Through implementation of full quality management, our company has passed

ISO9000 , SGS , IAF quality system certification. Our company has hired experts with technical expertise to ensure the

company to be at industrial leading position and technological frontier.

Our Sevice:

Pre-Sales Service

* Inquiry and consulting support.

* Planning layout and Design requires machinery

* Welcome visit our Factory.

After-Sales Service

* Engineers available to service machinery overseas.

* IN-TIME delivery goods.

* Free charges for installing, training and debugging.

* Long-term technical support.

Certification:

FAQ:

Q : Are you trading company or manufacturer?

A: We are manufacturer.

Q:How long is your delivery time?

A:Generally it is 60 days, it is according to quantity requires.

Q:What is the term of payment?

A: Payment <=1000USD, 100% in advance. Payment >=1000USD, 30% T/T in advance, balance before shipment.

Q:Do you have any Oversea Project?

A: Yes, we have service over 20 countries for their Plant set up Project.

If you are interested in this equipment, please don't hesitate to contact us!

If the machine is not suitable for your plant, please e-mail us the following information::

1. What’s the quality standard of billet do you want to casting? Is it common carbon steel or low carbon steel?

2. What’s the billet size and length?

3. Do you have melting furnace? If yes, how many tons of furnace with how many quantity?

4. What’s the capacity per hour?

According to your information, we will offer high efficiency design and best price for it.

-1465958238-0.jpg)

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية български

български hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Polski

Polski Română

Română русский

русский Svenska

Svenska 中文

中文