Company Profile Company Name:Geili Machinery (Fujian) Group Co., LtdContact Person:Vicky YuTel :86-594-6975208 Fax:86-594-6975166 Email:vicky@rerollingmillccm.com

Continuous caster

Description:

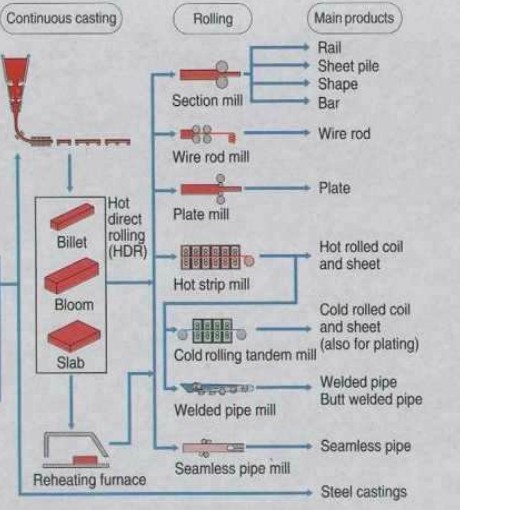

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Now "continuous casting" has evolved to achieve improved yield, quality, productivity and cost efficiency.This process is used most frequently to cast steel (in terms of tonnage cast). Aluminium and copper are also continuously cast.

Specification:

Machine model: continuous casting machineStrand quantity: as customer's demand

Radius: R3-14M

Casting type:round, square, rectangular billet

Steel quality: Common carbon steel; Bearing steel; Low alloy steel and stainless steel, etc.Annual output:100000-180000T/Y

Equipment:

Ladle

Ladle Turret

Tundish

Overflow tank

Operation box

Tundish car

Mould

Mould cover

Vibration device

Spraying nozzle

Guiding section

The withdrawl and straightening machine

Dummy bar

The storage device of dummy bar

Table roller

Hydraulic shear

Cooling bed

Inspection rack for the mould

Water cooling system

Hydraulic shear

Company Profile:

As a professional and experience manufacturer in China, we can supply whole production line from induction furnace, CCM and rolling mills. We can give turn-key service from foundation excavation, production line design, equipment manufacturing, installation and debugging, technician training depending on prominent capacity of designing and manufacturing and abundant practical experience of installation.

-1465958238-0.jpg)

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية български

български hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Polski

Polski Română

Română русский

русский Svenska

Svenska 中文

中文